What is a rare earth magnet?

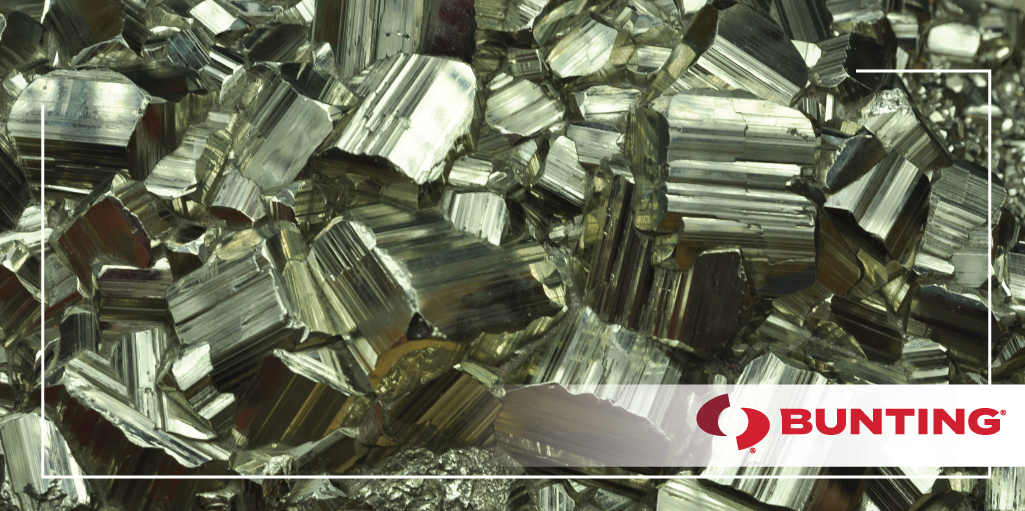

Magnets are defined as being “rare earth” if they contain rare earth elements. Looking at the periodic table, there are seventeen chemical elements classified as “rare earth elements.” Rare earth elements, including neodymium and samarium, belong to the lanthanide series of metallic chemical elements. For this reason, neodymium and samarium cobalt magnets are classified as “rare earth.”

Are they truly “rare”? Are they considered a limited resource?

As mentioned before, the name “rare earth” originates from the grouping of “rare earth elements” on the periodic table. Rare earth elements are not necessarily rare or scarce. Rather, within any given area of the Earth’s crust, the distribution of rare earth ores is uneven. This is in comparison to other elements, such as copper and tin, which are distributed in seams throughout the Earth’s crust.

How many different types are there?

There are two main types of rare earth magnets: neodymium iron boron magnets and samarium cobalt magnets. Neodymium iron boron magnets are the most powerful magnets currently in existence. Samarium cobalt magnets, while slightly less powerful than neodymium iron boron magnets, are sought out due to their superior heat resistance and corrosion resistance.

How powerful are they?

These magnets are the most powerful magnets in existence. They are able to contain intense, concentrated strength within very small dimensions. This makes them ideal for utilization in applications where size is a concern. Rare earth magnets are well suited for delicate applications within sensors, motors, and electronics, where high strength output is critical, yet space is very limited.

Are they dangerous?

It is important to handle these magnets responsibly due to their intense strength. Rare earth magnets must not be allowed to attract to each other from a distance, due to the fact that chipping or other breakage can occur when they crash together. These types of magnets must be handled cautiously around other electronics, especially in the case of medical devices such as pacemakers that utilize magnetic fields. While common sense precautions apply in handling these powerful magnets, there is no aspect of them that is independently “dangerous.”

Are these magnets durable?

Rare earth magnets are a durable, reliable material. To avoid physical damage such as chipping and breakage, they must be handled responsibly. Proper observance of maximum operating temperatures is important in order to avoid demagnetization. To resist corrosion and breakage, neodymium magnets are typically plated. Samarium cobalt magnets naturally have an greater resistance to heat and corrosion than neodymium magnets, so they are well suited for the most punishing environments.

What are these magnets used for?

Bunting-DuBois utilizes custom rare earth magnets and rare earth magnetic assemblies in many different applications spanning a broad range of industries. Examples of applications include sensors, motors, consumer electronics, medical devices, and oil filters. These types of magnets can be found in the automotive, aerospace, medical, defense, industrial, and electronics industries, as well as many more.