Oil & Gas

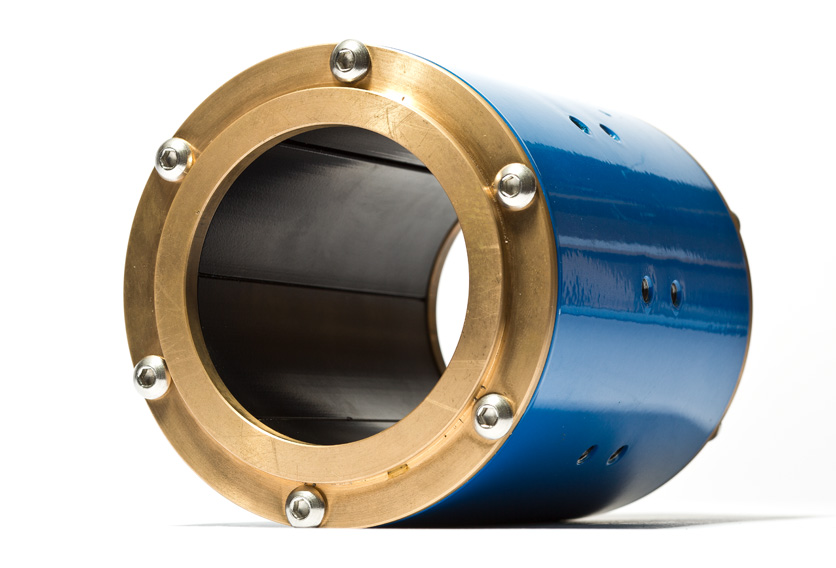

The oil and gas industry faces unique environmental factors, such as vulnerability to extreme temperatures and corrosion. We are experts in magnetic solutions that are used in sensors, couplings, filtration tools, separation tools, pumps, excavating tools, downhole magnetic tools, magnetic couplings, torque and steering motors, magnetic inspection devices, power generators, and much more.

We create the Custom Magnetic Assemblies you need Quickly, Reliably, and Consistently.

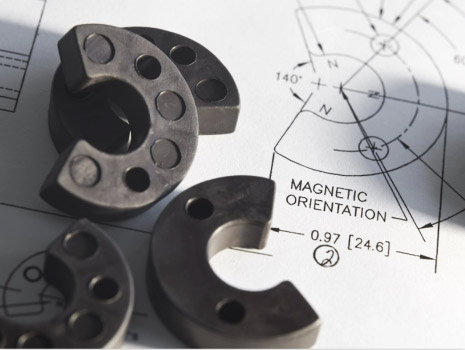

Custom Magnets and Magnet Applications for the Oil and Gas Industry

At Bunting-DuBois, we are experts in the design and manufacture of custom magnets and magnetic assemblies for customers working in the oil and gas industries. In oil and gas applications, there are many unique environmental factors to consider, such as vulnerability to extreme temperatures and corrosion. We work with customers closely throughout every step of the design process to provide them with a superior custom designed product that reaches the highest standards of durability and performance.

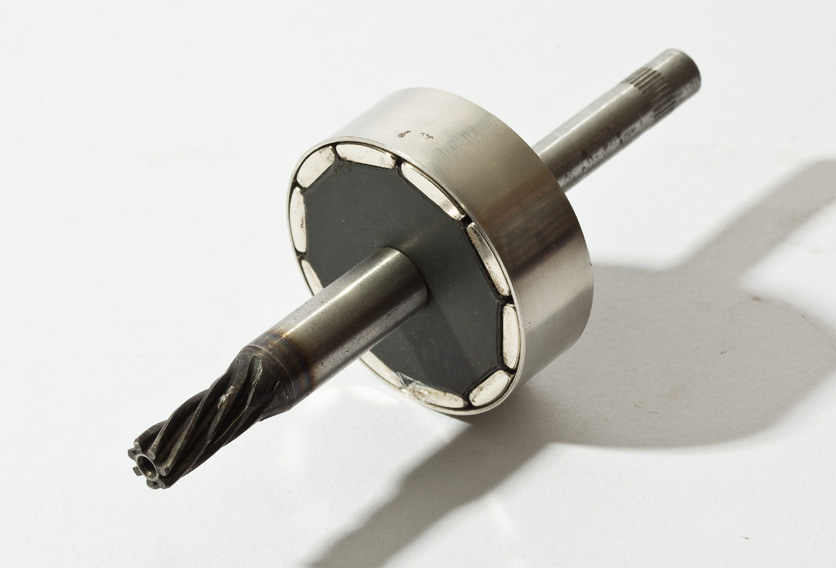

There are many aspects of the oil and gas industry that utilize magnets and magnetic assemblies. Sensors, couplings, filtration tools, separation tools, and pumps are just a few examples of the numerous areas magnets are used in the oil and gas industry. Other examples include excavating tools, downhole magnetic tools, magnetic couplings, torque and steering motors, magnetic inspection devices, and power generators. We are eager to work with you on your application and develop an expertly engineered solution according to your specifications.

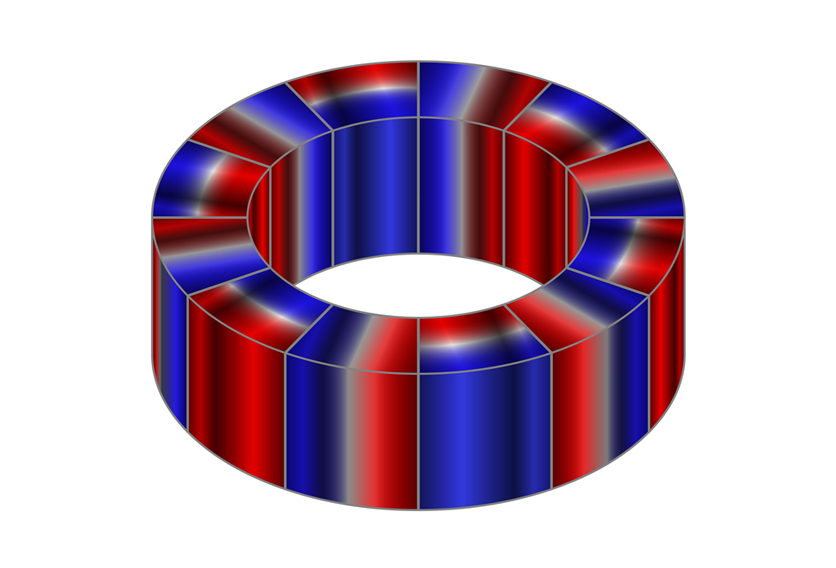

We are industry experts in high temperature samarium magnet assemblies, typically including stainless steel encapsulation and welding for pressure and vibration downhole applications. We offer a wide variety of material grades which have a high strength-to-weight ratio and will not lose attractive force over time, unless otherwise damaged. If you are in the early stages of selecting a magnet for your application, we will assist you in selecting the optimum material for your needs.

Custom Magnetic Products

Bunting-DuBois is your total magnet solution provider. We can supply any magnet material or magnetic assembly for your project. If it requires a permanent magnet, then we can do it!

Custom Magnets

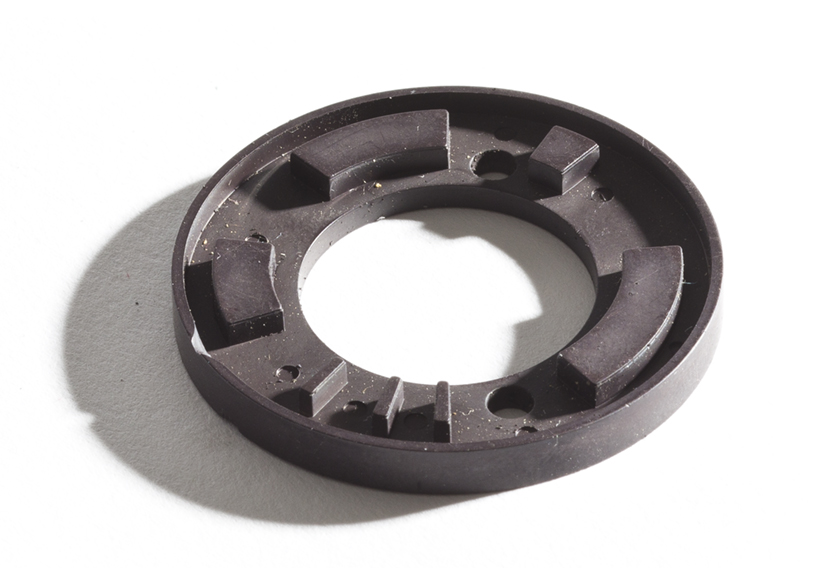

Custom Magnet Assemblies

Expertise at Every Step of the Process

At Bunting, we engineer a custom magnet to fit your specific needs. We combine ingenuity, our deep expertise and our dedicated range of equipment in order to deliver you the exact product you need with no sacrifice to quality design and engineering.

What You Can Expect From Bunting

- 2D and 3D magnetic modeling of your design

- Rapid prototyping of designs

- Capacity to manufacture magnets + magnetic assemblies in any quantity

- Extensive quality checks of product

- On-time delivery