Custom Rare Earth Magnets

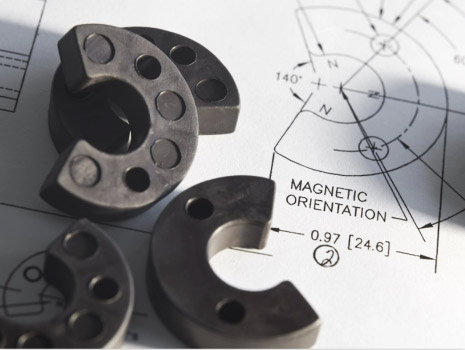

Design Consulting for Custom Permanent Magnets

Permanent magnets are essential to virtually every type of modern technology and convenience. Being able to provide the optimum magnetic solution to the customer requires in-depth knowledge of the full supply chain. Bunting’s team of magnet experts and engineers is fully equipped with this knowledge. Bunting entered the magnetics industry in 1959 as a magnet distributor and rapidly grew to a manufacturer of magnetic products, focused on custom design and customer-focused engineering. Today, Bunting is a leader in manufacturing and designing a diverse range of innovative magnetic technologies across industry sectors.

Manufacturing custom magnets with superior magnetic materials

Manufactured in DuBois, Pennsylvania, Bunting is the only North American manufacturer of compression bonded, injection molded and hybrid magnets. In addition, we provide a complete range of permanent magnet types including sintered neodymium magnets and magnetic assemblies. Our exclusive NeoBlend™ bonded neodymium magnets can be designed to any size, shape or strength thanks to a complete range of presses from 4-ton to 200-ton.

Bunting engineers are ready to assist you with the important task of magnet material selection. Our material selection includes the full range of NdFeB grades including radial rings and the latest high temperature grades for the most demanding applications. The design considerations include thermal properties, mechanical properties, cost, energy product, corrosion resistance, electrical conductivity and more.

Industrial-Strength Rare-Earth Magnets

Ceramic Ferrite Magnets

Ceramic magnets, or ferrite magnets, are low cost, lightweight, moderate energy permanent magnets capable of withstanding operating temperatures of up to 480°F. They are highly corrosion resistant and work well in high volume applications. These qualities make them a popular choice in manufacturing and consumer applications such as speaker magnets, DC motors, reed switches, sweepers, MRIs, and automotive sensors.

Alnico Magnets

Alnico magnets are alloys comprised of aluminum, nickel, iron, and cobalt. They have the highest operating temperature and temperature stability of any permanent magnetic material. They retain approximately 85% of room-temperature magnetization at temperatures of up to 1,000°F. They possess high residual induction as well as relatively high energy products. Alnico magnets naturally possess an excellent corrosion resistance. This makes surface treatment unnecessary, although they may still be easily plated if desired. Alnico magnets may be produced by either casting or sintering.

Samarium Cobalt Magnets

Samarium cobalt magnets are rare earth magnets that offer high maximum energy products and can operate in high temperature environments. They are extremely strong and typically allow for smaller size magnet profiles. Though not as strong as neodymium magnets, samarium cobalt magnets present three significant advantages. They work over a wider temperature range, have superior temperature coefficients, and have a greater resistance to corrosion. Special coatings are available for specific marine and automotive applications.

Neodymium Magnets

Neodymium magnets are a type of rare earth magnet and are the most common rare earth permanent magnets in the world. They are composed of Neodymium (Nd), Iron (Fe) and Boron (B), and exhibit the highest maximum energy product of any permanent magnet material. However, these magnets are vulnerable to corrosion. To protect the magnet from corrosion, the magnet is usually coated with nickel. Other coating options are aluminum, zinc, tin, copper, epoxy, silver and gold.

Injection Molded Magnets

Injection molded magnets are available in both neodymium and hard ferrite materials and are often used in large quantities for various applications. What makes these especially useful is that they provide seemingly endless shapes and sizes while maintaining magnetic strength. They are made by mixing magnetic materials with a polymer binder, like nylon or polyphenylene sulfide.

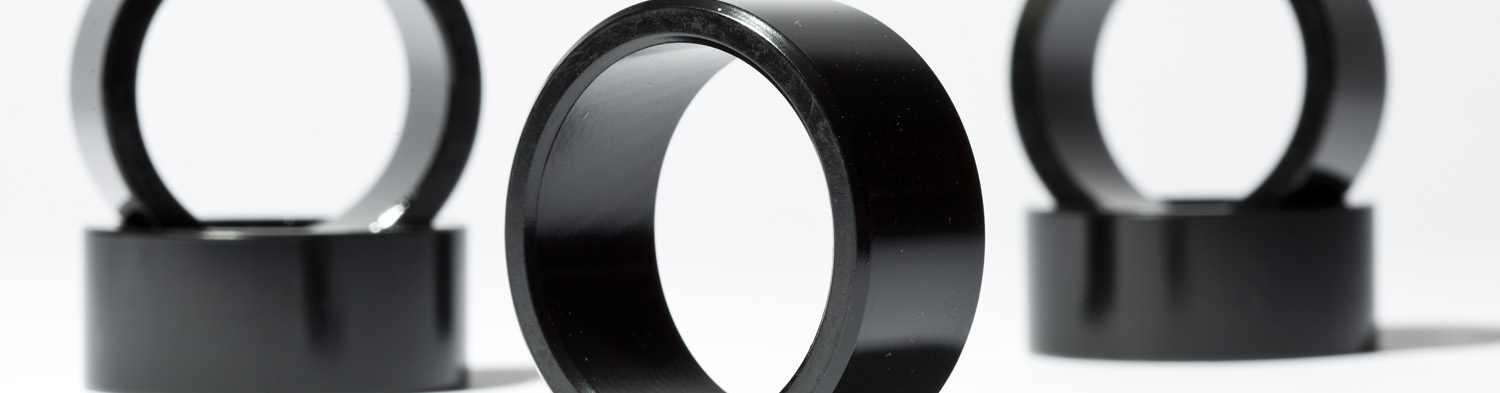

Compression Molded Magnets

Compression molded magnets are generally used in applications that require the highest magnetic performance for a bonded magnet. They are often produced in very high quantities. Compression molded magnets are more cost-effective than injection molded magnets, but are limited to simple shapes like rings, cylinders, and rectangles.

Bonded Magnets

Bonded magnets are a highly versatile material with multiple processing options. They have good mechanical properties and higher electrical resistivity than sintered magnets. Bonded magnets are available in complex shapes and have excellent geometric tolerances. Bonded magnets consist of two components: a hard magnetic powder and a non-magnetic polymer or rubber binder.

Custom Magnets for diverse applications

Magnets for Motor Assemblies

In motors, Samarium Cobalt (SmCo) magnets are often used due to the tolerance for high temperatures and magnetic strength. The maximum temperatures for SmCo magnets are between 250 and 550 °C. SmCo are also corrosion resistant, while the Neodymium counterparts are not, therefore surface coatings are not necessary for most applications. This allows for broader use in medical applications.

Magnets for Loudspeakers

Most loudspeakers have ferrite magnets inside, which can be produced for larger, higher output speakers. Ferrite magnets also resist corrosion, which is helpful for outdoor audio systems. Ferrite is also the more cost-effective material for production. Neodymium magnets are also used in higher-end loudspeakers and smaller speakers in automobile applications.

Magnets for Sensing and Switching Assemblies

At the core of sensing and switching assemblies lies the strategic integration of magnets, enabling accurate detection and control of various parameters. By harnessing the power of magnetism, these assemblies offer a versatile and responsive solution for industries such as automotive, manufacturing, and home automation.

Position Sensing (Rotary and Linear) Magnets

In rotary position sensing, magnets enable the detection and measurement of angular displacement with exceptional accuracy. The magnetic field interacts with a rotating target, generating a proportional electrical signal. This signal is then processed to determine the precise position of the rotating object, enabling precise control and monitoring in various applications.

Magnets for Hard Drives

At the heart of hard drives lie powerful magnets meticulously engineered to interact with key components, enabling data to be written, stored, and retrieved with remarkable precision. These magnets play a vital role in the overall functionality of the drive, enhancing its speed, capacity, and durability.

Custom Magnets for Your Market

Bunting offers first-hand, unmatched magnet and industry experience. In order to meet the requirements of modern applications, we can provide a full range of materials covering numerous product geometries, grades and processing operations while achieving superior product quality.