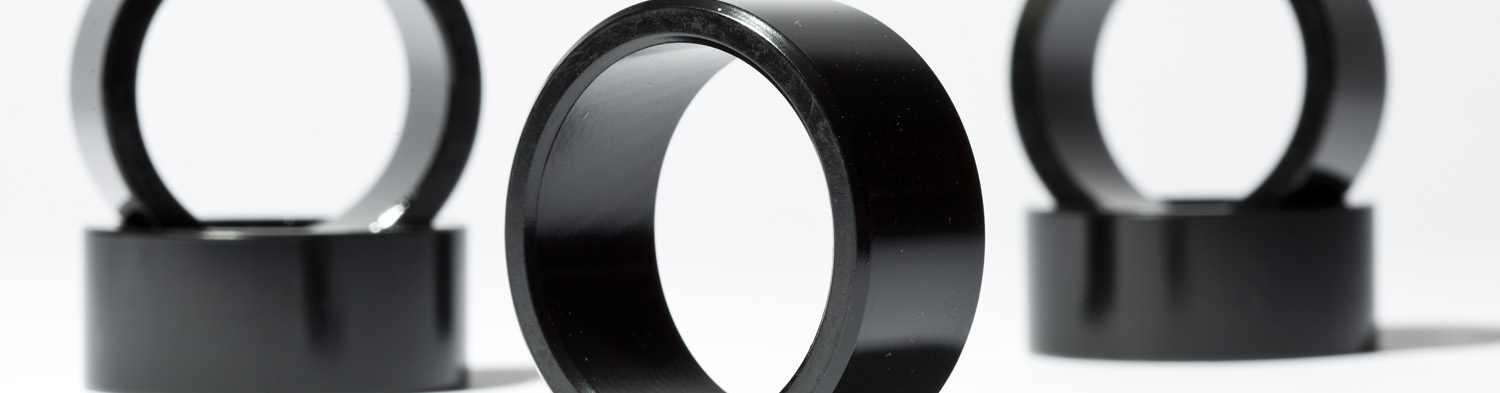

Bonded Magnets

Bonded magnets are available in complex shapes and have excellent geometric tolerances.

- Popular resin bonded magnet (resin bonds particles during the compression bonded or injection molded process)

- Available up to 12 MGOe and with a coating

- Typical applications include encoders and BLDC motors

- Temperature limit of 150°C

- Low cost, low electrical conductivity

Custom Bonded Magnets

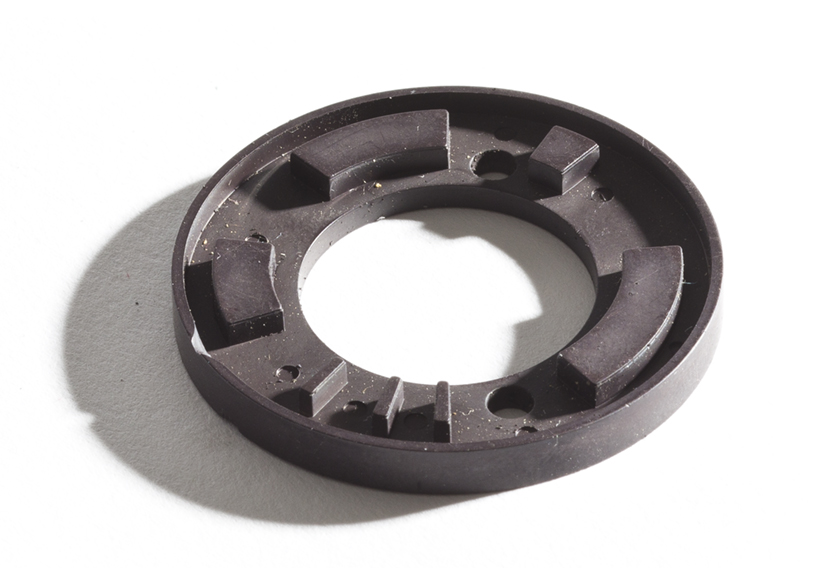

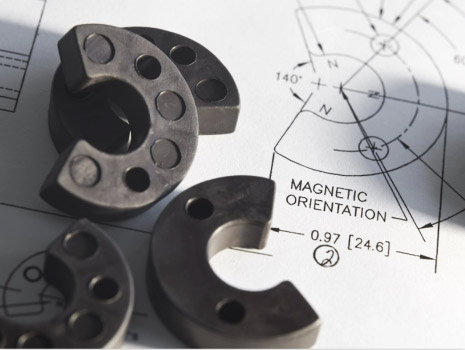

Bonded magnets are a highly versatile material with multiple processing options. They have good mechanical properties and higher electrical resistivity than sintered magnets. Bonded magnets are available in complex shapes and have excellent geometric tolerances. Bonded magnets consist of two components: a hard magnetic powder and a non-magnetic polymer or rubber binder. The magnetic powder can be made from any kind of magnetic material, including hard ferrite and alnico as well as rare earth materials such as neodymium iron boron and samarium cobalt. The magnetic powder may also be a hybrid mixture of two or more magnetic powders. These are especially well suited for applications such as minimizing cogging torque in motors. These compression bonded magnets are an excellent choice for higher volume applications. Compression bonded magnets can also be easily machined, making them suitable for low volume production in manufacturing magnets with multipole magnetization, skew angled poles, and various other directions of magnetizations. Magnetizing patterns are only limited by whether a magnetizing coil fixture can be produced to give the required magnetizing pattern.

- Bonded NdFeB magnets can be compression or injection molded to net shape. These high tolerances can be achieved without the need for further machining.

- Injection molded magnets are available in both neodymium and ferrite varieties.

- Injection molded ferrite magnets offer high durability and resistance to shock, as well as a low cost and extreme resistance to corrosions and conditions such as low density.

- Available in high tolerance and complex shapes.

- No coating required, although black epoxy and Parylene coatings are available.