Bonded magnets are a lesser known, but still highly important group of products that should be considered by magnetic circuit and device designers when selecting the best type of permanent magnet for their application. To provide a very basic definition, bonded magnets consist of two components: a hard magnetic powder and a non-magnetic polymer or rubber binder. The magnetic powder can be made from any kind of magnetic material, including hard ferrite and alnico as well as rare earth materials such as neodymium iron boron and samarium cobalt. The magnetic powder may also be a hybrid mixture of two or more magnetic powders.

No matter what magnetic material the powder is made of, the powder’s properties are carefully optimized through chemistry and processing that specifically aims at utilization in a bonded magnet. There is further opportunity for unique design when selecting the binder material that holds the magnetic particles in place, as this can result in either a rigid or a flexible magnet being produced. Most commonly, flexible magnets use vinyl or nitrile rubber as binders.

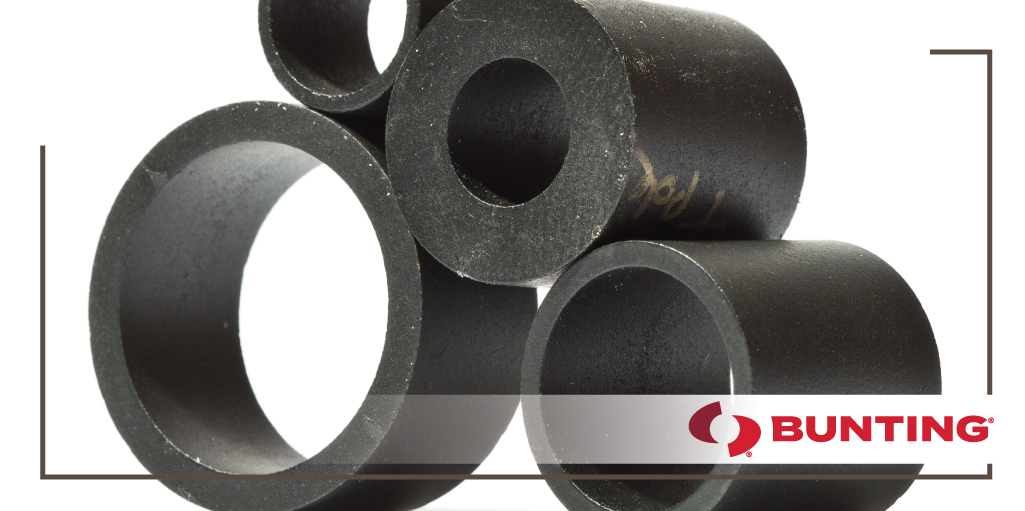

When designing a rigid magnet, common binder materials include polyester, nylon, PPS, thermoset epoxies, and Teflon. Thermoplastic binders can be formed into a sheet by using a calendaring or extrusion method. Alternatively, injection molding can be used to form material into various complex shape. In compression bonding, the process almost exclusively involves isotropic neodymium iron boron powders being combined with a thermoset epoxy binder using a uniaxial room temperature pressing process. One of the major advantages of bonded magnet processing is near net shape manufacturing that requires zero or minimal finishing operations in comparison to powder or cast metallurgical processes. This also means that value added assemblies are able to be produced economically in a single operation.

Bonded magnets are a highly versatile material with multiple processing options. They are a diverse contribution to the portfolio of permanent magnet materials available to device designers. Bonded magnets offer many unique advantages in terms of both product form as well as value added assembly capabilities.

There are many unique benefits of bonded magnets.

They have good mechanical properties and higher electrical resistivity in comparison to sintered magnets. Bonded magnets are available in complex shapes, and have excellent geometric tolerances with minimal or no secondary operations. Bonded magnets are also available with multipole magnetization, and have a tailored flux output for the given size and shape of the magnet.

Bunting-DuBois, located in DuBois, PA, is one of the largest North American manufacturers of ferrite and neodymium iron boron injection molded magnets, as well as one of the largest manufacturers of compression bonded neodymium iron boron magnets. Bunting-DuBois also supplies a full range of permanent magnets and magnetic assemblies.

To learn more about bonded magnets, contact Bunting-DuBois today.