MQ3 Fully Dense NdFeB Magnets

By Dr. John Ormerod

Technical Adviser / Bunting-DuBois

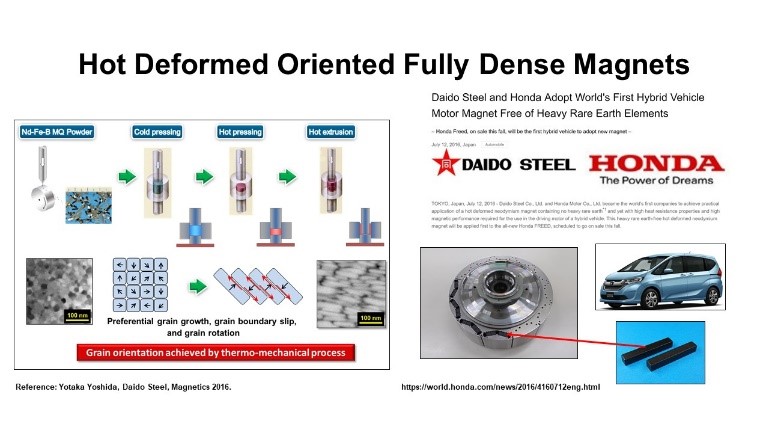

Fully dense NdFeB magnets can also be produced from melt spun powders by a combination cold pressing, hot pressing and thermomechanical forming technologies.

This process was originally developed by Magnequench and is known as the MQ3 process. Grain orientation in MQ3 magnets is developed through mechanical reorientation of the microstructure during the hot forming step. In 2016 Daido Steel and Honda announced they were forming a JV to produce MQ3 fully dense oriented magnets for HEV traction motors with zero heavy rare earth element (HREE) content.

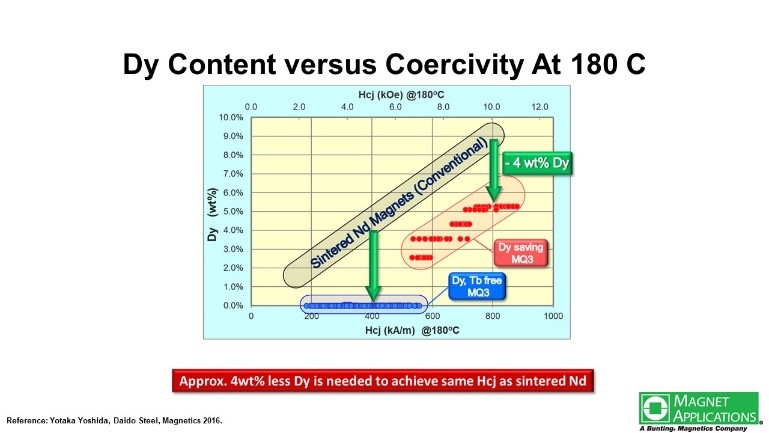

So why is no HREE required in MQ3-type magnet in a HEV traction motor application? Since these magnets start with a melt spun alloy they have a much finer grain size, by at least a factor of 10, than sintered magnets which enhances the baseline coercivity. This in turn requires a lower Dy content than the equivalent sintered magnet composition. Typically, a 4 wt.% saving. However, according to the data shown if the motor design can tolerate a Hc of 7 kOe or less at 180 C no HREE additions are required.