Fully Dense Rare Earth Magnets by Powder Metallurgical Processing

By Dr. John Ormerod

Technical Adviser / Bunting-DuBois

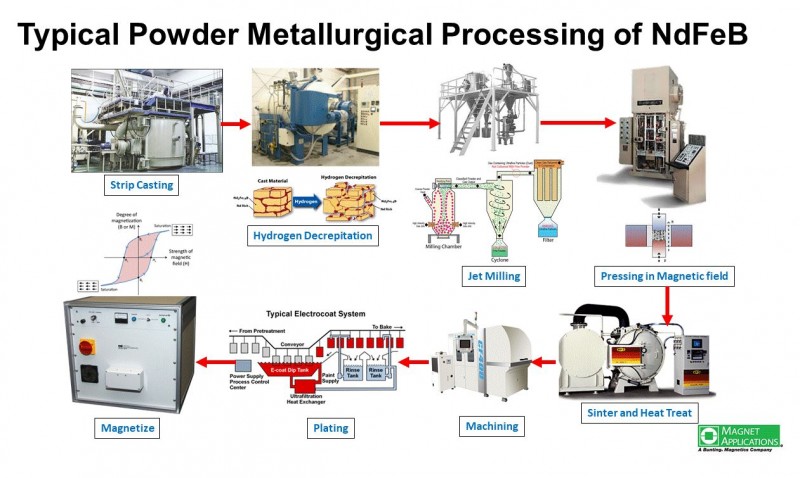

The powder metallurgical method is the most common method of manufacturing fully dense NdFeB (and SmCo-based) magnets. Below is an outline outline that is typical for NdFeB magnet production process.

Today strip casting is the preferred method alloy production. During strip casting the melt and is cooled and solidified at approximately 10,000 C/sec. This rapid cooling is found develop the optimum microstructure and phase distribution of the starting alloy.

The next process step is coarse crushing of the strip cast alloy using the hydrogen decrepitation process followed by jet milling to a narrow particle size distribution centered around 5 um. This process produces a powder consisting of single crystal Nd2Fe14B particles while eliminating ultrafine RE rich particles. The resultant powder is then pressed in either a uniaxial or isostatic pressing system.

A magnetic aligning field is applied during pressing to achieve orientation of the alloy particles and create an anisotropic preferred magnetization direction in the finished magnet. The resultant green compact is then sintered to full density and heat treatment under inert gas or vacuum atmosphere to develop the final magnetic properties of Br, Hc and (BH)max.

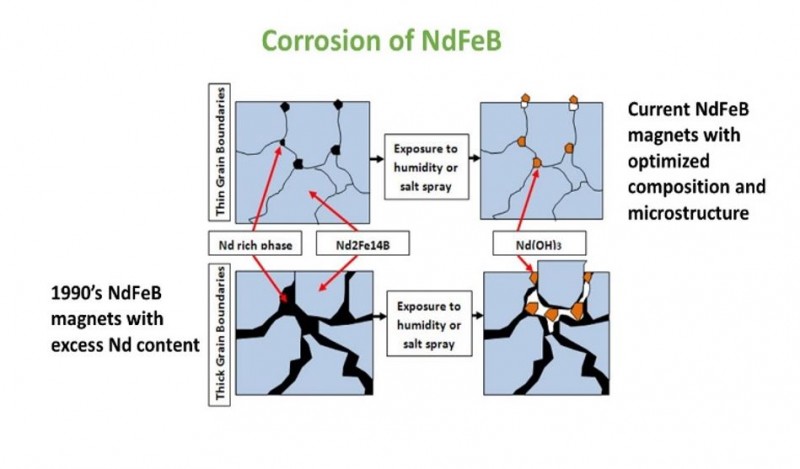

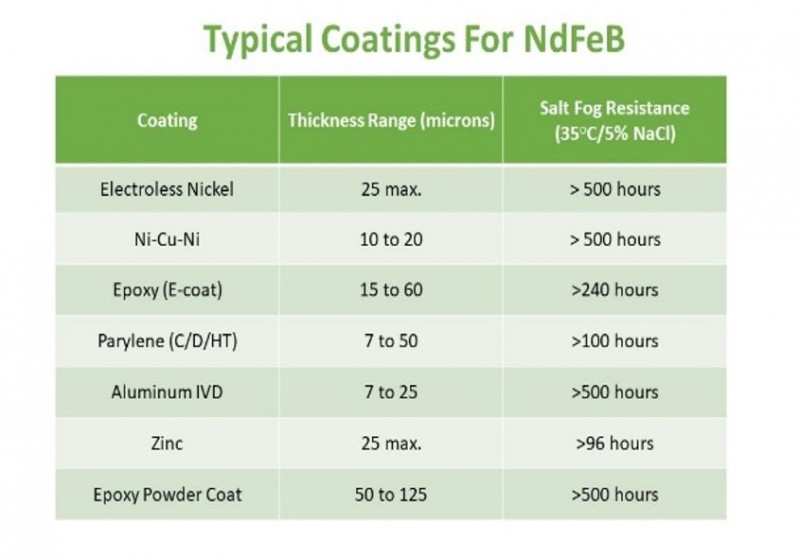

The fully dense parts are then machined to meet dimensional requirements. Because of the poor corrosion resistance of NdFeB the magnets are coated to provide the necessary corrosion protection. Over recent years improvements in alloy chemistry and microstructure has improved the corrosion resistance of NdFeB magnets as show in the adjacent diagram. However, in most applications a coating is required for guaranteed corrosion protection. The most common coatings are shown in the table below.

The magnets are inspected for magnetic, dimensional, physical and other customer defined characteristics and finally magnetized either at the magnet suppliers location or during assembly at the customer site.