Injection Molded Ferrite

We offer complete engineering assistance, prototyping services, fabrication and inventory stocking.

- Ideal for large production runs

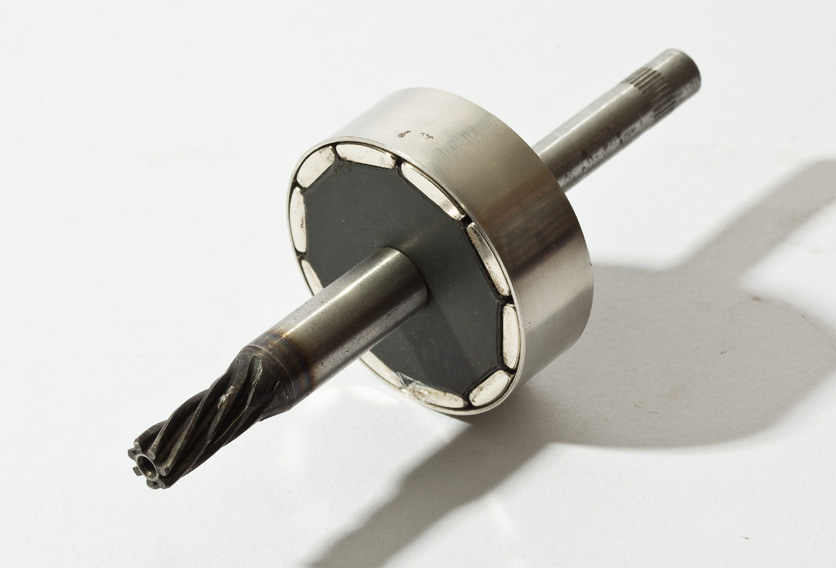

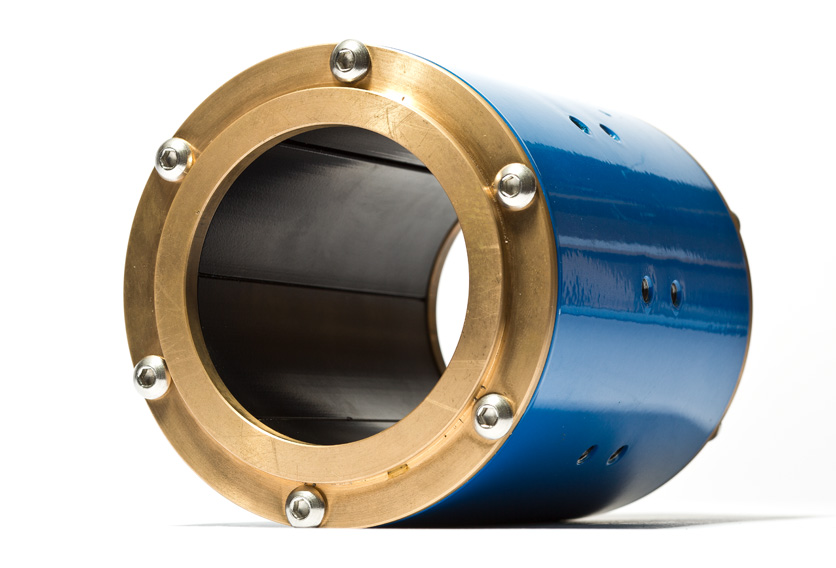

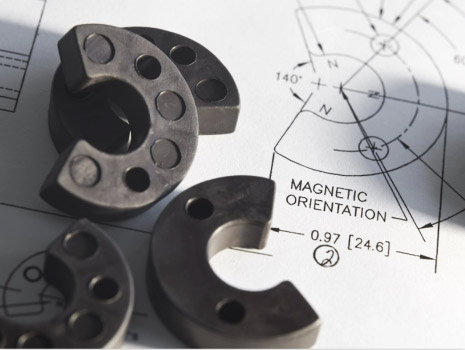

- May be molded into complex shapes

- May be molded onto shafts or to be attached to other components

- Tolerances as tight as 0.01 mm

- Impact and chemical resistance

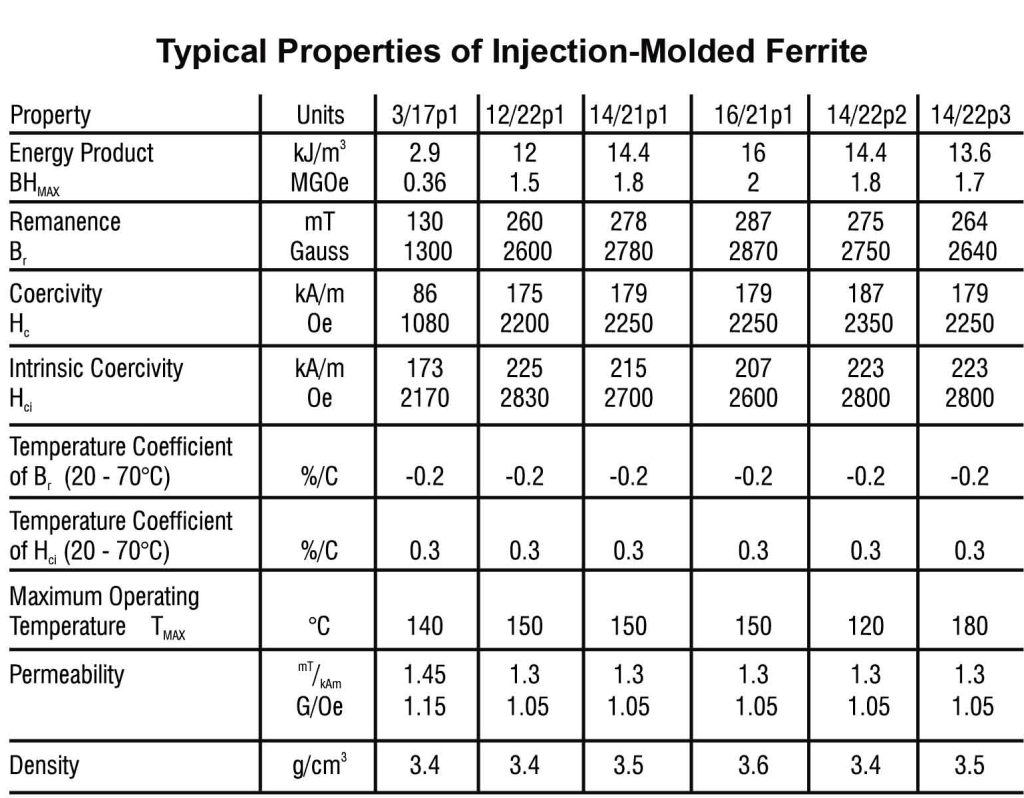

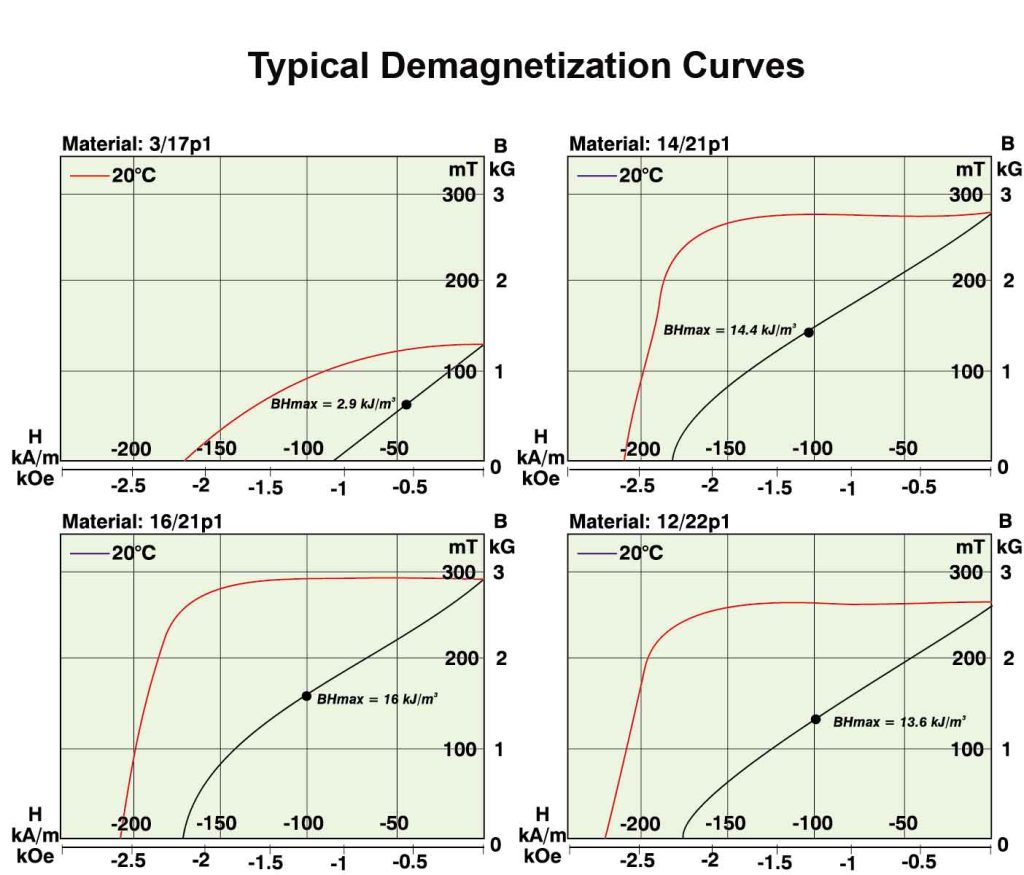

- Energy products to 16 kj/m3

- Isotropic and Anisotropic grades

- Neodymium hybrids can increase performances

- Co-injected assemblies

Custom Injection Molded Ferrite Magnet Assemblies

Bunting-DuBois Injection Molded Ferrite magnets offer design engineers near limitless shape and magnetization possibilities. Its high tensile strength allows injection-molded components to withstand high rotational forces, and it offers both excellent chemical and impact resistance.

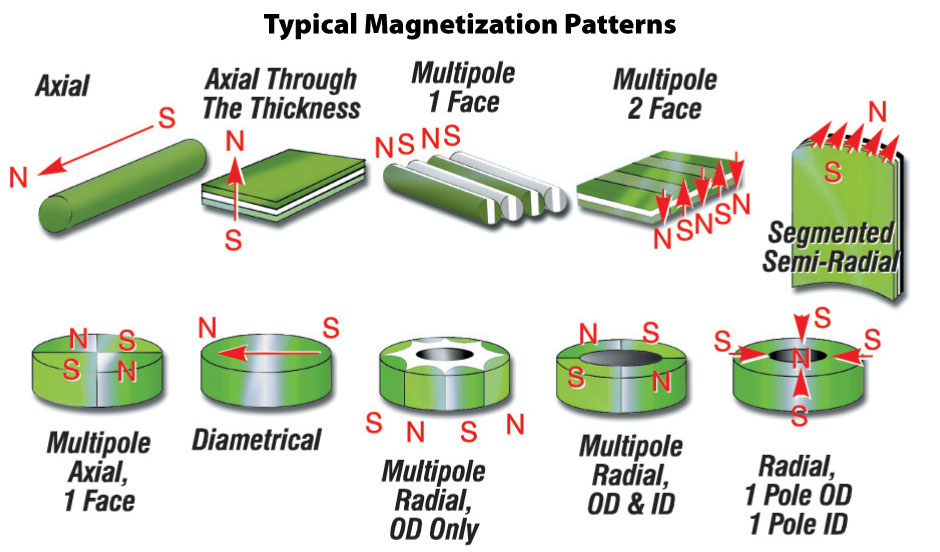

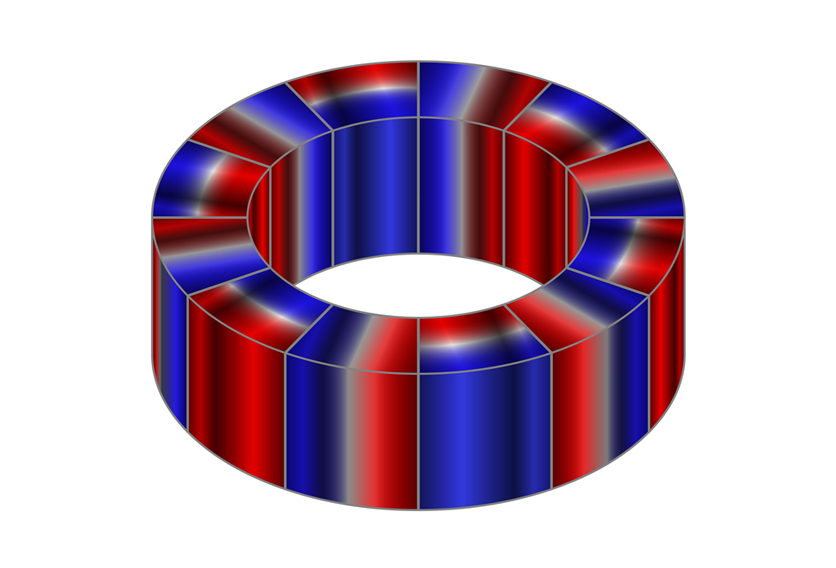

Isotropic grades can be magnetized in any direction (axial, radial or multipolar). Anisotropic grades are magnetically oriented in a preferred direction during the molding process and offer higher energy products.

Our experts have had great success with new hybrids of Neodymium Iron Boron and Ferrite magnets, offering our customers an even broader range of choices. We offer complete engineering assistance, prototyping services, fabrication and inventory stocking.