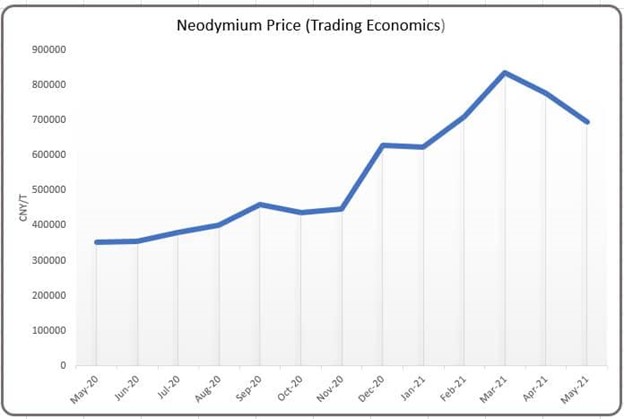

In March 2021, the price of neodymium metal reached a 9-year high, having risen by 42% since the start of the year (Trading Economics). As of early May 2021, the price began to drop slightly, but the short term and long-term projected price trends remain uncertain.

Magnet and Magnetic Assembly Design

Bunting constantly seeks to support cost effective manufacturing of high-quality magnets and magnetic assemblies. The company is able to help limit the effect of price uncertainty by focusing on maintaining a diverse supply chain, effective production, and cost-efficient engineering advice.

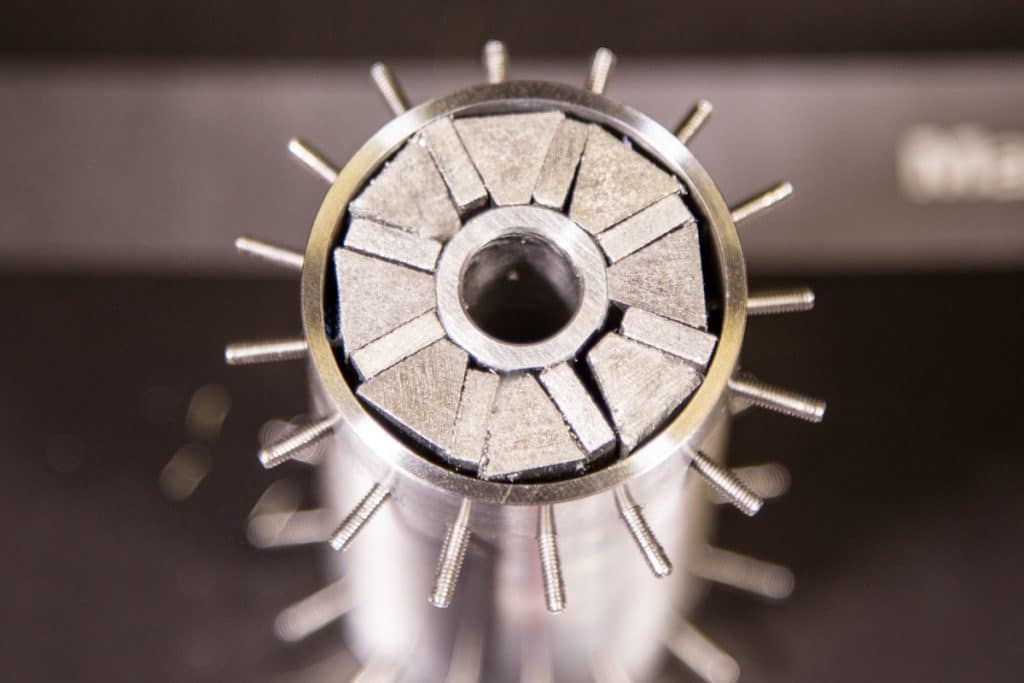

When designing a magnet assembly, the cost of the magnetic material involved may ultimately only reflect a third or less of the greater system cost. In this scenario, overall costs are reduced by Bunting’s ability to, for example, provide advice regarding cost effective shaft design vs magnet geometric profiling. There are other various cost-saving decisions that can be made as well. For example, looking at Halbach arrays, this type of design is typically used in high performance rotors, which greatly increases the difficulty of traditional assembly and, as a result, cost. However, these types of designs are excellent for in-house post-assembly magnetization, where there will be significant savings in time and cost, as well as de-risking the entire production process. To engineer the optimum solution for each unique application, Bunting engineers work closely with customers throughout every step of the design process.

At Bunting, our engineers work to assess different techniques in order to determine how to get the most performance out of the magnet, without simply increasing the magnet’s size (leading to higher cost) or using higher coercivity grades (leading to both higher cost and often lower strength).

The usage of grain boundary diffused dysprosium has been a critical area of magnetic technology development. Grain boundary diffused dysprosium is able to enhance the coercivity of a neodymium magnet without using traditional methods that cause a drop in the total energy product. During this secondary manufacturing process, the heavy rare earth element dysprosium is concentrated into the grain boundaries of the magnet microstructure. By doing this, there is not only a performance increase, but also a cost decrease. By using less dysprosium in this method, the result is a more stable price compared to traditional method magnets.

At Bunting, we strongly believe the best end solutions are achieved when both design teams are able to work together from the outset. Additionally, we seek to minimize costs and maximize performance by continuously seeking out innovative new technology and manufacturing techniques.

Neodymium: A Key Raw Material

Neodymium is a critical rare earth material that is widely used in rare earth magnet applications in automotive components, electronics, and, of particular note, the growing clean-energy sector that relies on technology such as wind power and electric vehicles. Currently, 80% of rare earths are sourced and produced in China. However, the U.S. is making it a top priority to reduce dependence on China for the sourcing and production of rare earth materials. Reliance on China is undesirable due to both economic and political concerns.

Bunting-DuBois is significantly ahead of the game in terms of reducing reliance on China. Instead of relying solely on China, Bunting-DuBois has a diversified supply chain, and sources material for injection molded and compression bonded magnets from Australia before sending the material to Malaysia for processing. Then, once the material arrives in the U.S., it is made into custom injection molded and compression bonded magnets at Bunting-DuBois in Pennsylvania. By structuring a diverse supply chain, Bunting-DuBois was able to avoid a great deal of chaos that occurred as a result of China shutting down during the COVID-19 pandemic.

In 2019, global consumption of neodymium iron boron magnets was 105,300 tons. It is expected that consumption will grow by 7.5% each year, and the growing demand for use in electric vehicles is expected to account for 40% of the total by 2030. Currently, each electric vehicles uses between 4 to 11 lbs of rare earth magnets. According to the International Energy Agency, there could be 230 million electric vehicles worldwide by the year 2030. At an average of 7.7lbs of rare earth magnets per vehicle, this would equate to 805,000 tons total.

Magnet and Magnetic Assembly Design

As costs for neodymium, samarium cobalt, and other rare earth materials continue to increase, Bunting is committed to helping customers find cost-efficient solutions to their problems. Our expertise in the design and manufacture of custom magnets and magnetic assemblies allows us to provide superior products while maintaining cost efficiency.

To learn more, contact Bunting-DuBois today.