Permanent magnets and magnetic applications have long played a key role in driving innovation and higher performance in the automotive industry. At Bunting-DuBois, we have supplied millions of parts to a wide variety of automotive suppliers—and that number is growing each day. Our developments in automation allow us to reliably supply high-volume orders, making us a key supplier of some of the most essential—but rarely acknowledged—automotive components and devices.

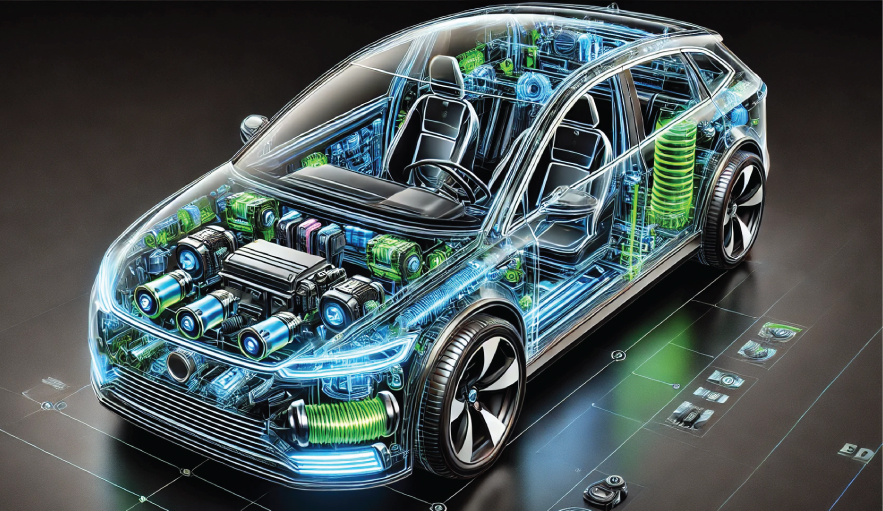

In the past few decades, cars have transformed from electro mechanical control systems to sophisticated electronic control systems in numerous vehicle control and engine management systems. This is in contrast to more widely used pneumatic, hydraulic, and mechanical control systems of the past. This shift to electronic controls has significantly increased demand for magnets to support various systems within vehicles, including sensors, actuators, and motors.

Magnetic Applications are key components of vehicle performance, safety, and convenience in the Automotive Industry.

Many different types of magnetic materials are used in vehicle systems, including high-energy product neodymium iron boron magnets, corrosion-resistant samarium cobalt magnets, durable alnico magnets, and economical ceramic magnets. There are several different factors that must be considered in selecting an appropriate magnet for an automotive application, such as the maximum temperature the magnet will be exposed to, how much space is available, and how much a certain magnet may cost. To assist customers in selecting the ideal magnet for their automotive application, DuBois engineers offer extensive design assistance, as well as rapid prototyping capabilities that allow for hands-on experimentation.

Looking at a vehicle, we can see many places where customers may be seeking to implement a magnet or magnetic assembly. For example, ceramic magnets can be used in anti-lock braking systems (ABS) to improve driver safety and make roads a safer place for everyone to drive on. Neodymium magnets concentrate exceptionally high power into a much smaller size of magnet compared to other available magnet materials, and they are an excellent choice for magnetic applications that require a lightweight magnet or a magnet that can fit within limited dimensions. Today, rare earth magnets are used in electric vehicle drive trains as an environmentally friendly way to increase vehicle efficiency without sacrificing performance.

Magnets are used in many other vehicular mechanisms, including transmission and oil pan chip collectors, fuel pumps, airbag actuators, steering sensors, power seat and power window motors, dashboard instruments, and even loudspeakers in a car’s stereo system. Magnetic sensors are perhaps the most noticeable application of magnets—for example, whenever your low tire pressure light comes on, it is a result of a magnetic sensor. Whenever you turn your windshield wipers on, those motors are also powered by magnets.

Magnetic applications for the automotive industry are key components of vehicle performance, safety, and convenience. There are many ways magnetic applications can be utilized in automotive applications, and at Bunting-DuBois, we can assist you in designing a custom magnet or magnetic assembly for any of them. To speak to our experienced team of engineers about your automotive project, Contact Us Today.