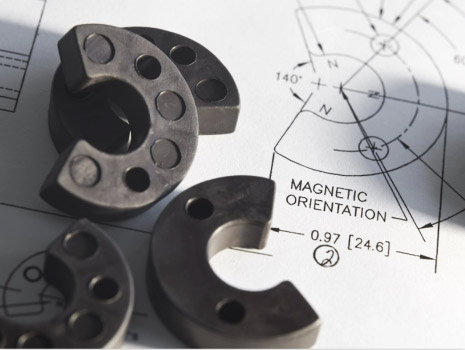

Magnetization

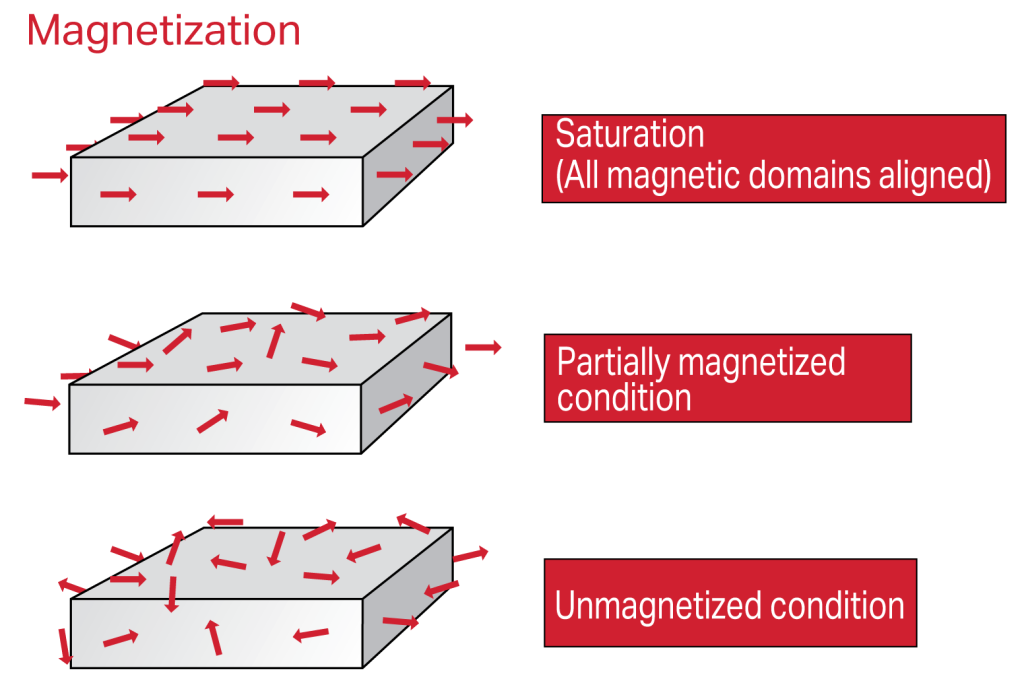

Permanent magnet materials are believed to be composed of small regions or “domains” each of which exhibit a net magnetic moment. An un-magnetized magnet will possess domains which are randomly oriented with respect to each other, providing a net magnetic moment of zero. Thus, a magnet when de- magnetized is only de-magnetized from the observer’s point of view. Magnetization is achieved by exposing the magnet to a very high magnetic field, the strength of which depends on the type of magnet material. The magnetic field aligns the domains to give a net, externally observable field.

Magnetization & Magnetizing Equipment

The initial objective of magnetization is to magnetize to saturation, even if it will be later demagnetized for stabilization. Magnetization is accomplished by exposing the magnet to an externally applied field, which can be created by other permanent magnets or by currents in coils.

The use of permanent magnets is only practical for low coercivity or thin sections of material. Removal of the magnetized specimen from the permanent magnet magnetizer can be problematic since the field cannot be turned off and fringing fields may adversely affect the magnetization of the part.

The two most common types of magnetizing equipment are the DC and Capacitor Discharge magnetizers.

Saturation Fields Required

Some rare-earth magnets require very high magnetizing fields in the range of 20 to 50 kOe. These fields are difficult to produce and require large power supplies with carefully designed magnetizing fixtures. Isotropic bonded NdFeB materials require magnetic fields in the range of 60 kOe to be fully saturated. However, 98% of saturation may be achieved by fields near 30 kOe. Ceramics require fields near 10 kOe, while Alnicos require fields near 3 kOe for saturation. Because of the ease by which Alnico 5 can become inadvertently demagnetized, it is preferable for this material to be magnetized just prior to or even after final assembly of the magnets into the device.

It is important when magnetizing a magnet to always magnetize it to saturation, even if it will subsequently be slightly de-magnetized for calibration or stabilization purposes. Saturating the magnet and then de-magnetizing it in a controlled manner ensures that the domains with the least commitment to orientation will be the first to lose their orientation, thereby leading to a more stable magnet.

Not achieving saturation, on the other hand, leads to orientation of only the most weakly committed domains, leading to a less stable magnet.

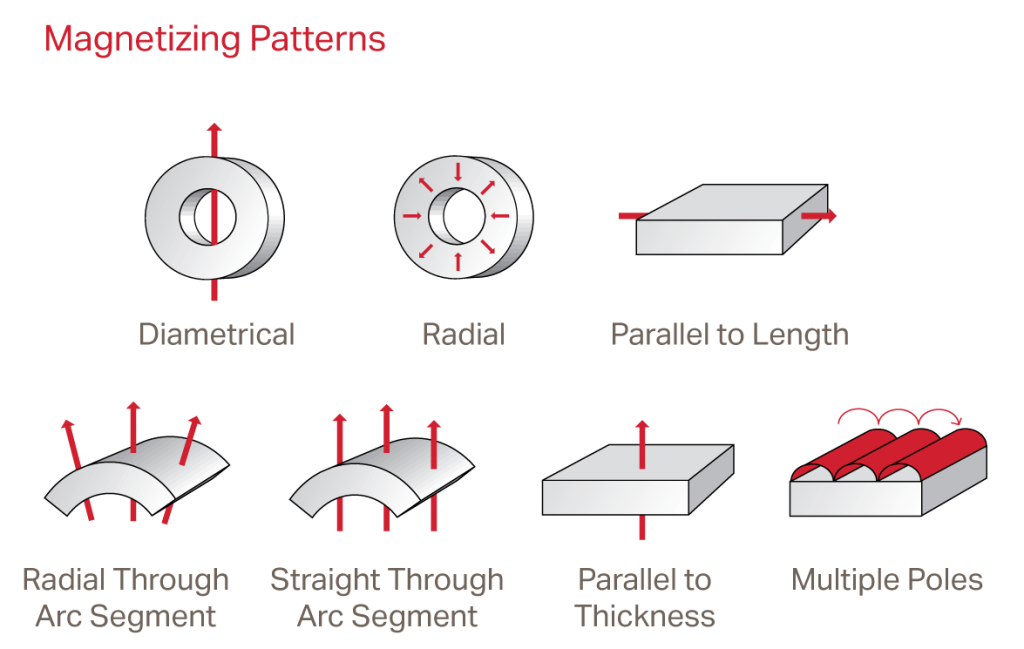

In general, permanent magnets are supplied with a simple 2 pole magnetization pattern, a North pole on one face and a South pole on the opposite face. However by appropriate configuration of the magnetizing coils it is possible to construct a fixture that will magnetize a magnet with many pole-pairs, and for some materials, pole patterns on a single surface of the magnet. This is called multi-pole magnetization.

Multiple Pole Magnetization

In certain cases, it may be desirable to magnetize a part with more than one pole on a single pole surface. This may be accomplished by constructing special magnetizing fixtures. Multiple pole magnetizing fixtures are relatively simple to build for Alnico and Ceramic, but require great care in design and construction for rare-earth materials. Magnetizing with multiple poles will sometimes eliminate the need for several discrete magnets, reducing assembly costs, although a cost will be incurred for building an appropriate magnetizing fixture. Multiple pole fixtures for rare-earth magnets may cost several thousand dollars to build, depending on the size of the magnet, the number of poles required, and the fields necessary to achieve saturation.

Anisotropic magnets, typically sintered magnets such as sintered NdFeB or ceramic magnets, have a preferred direction of magnetization which gives them higher magnetic properties than isotropic magnets of the same material. These magnet materials must be magnetized parallel to the preferred direction to achieve these optimum magnetic properties. Consequently, these materials are not generally suitable for multi-pole magnetization and such assemblies have to be constructed from individual pre-magnetized segments. However, isotropic magnets have no preferred direction and can therefore be magnetized in any direction making them ideally suitable for multi-pole magnetization in a single operation. This is one of the key advantages of BREMAG® bonded magnets. BREMAG® is a trademark of Bunting-DuBois bonded materials.

General Categories of Permanent Magnets:

- Mechanical to Mechanical: Such as attraction and repulsion

- Mechanical to Electrical: Such as power generation and microphones

- Electrical to Mechanical: Such as motors, loudspeakers and charged particle deflection

- Mechanical to Heat: Such as eddy current and hysteresis torque devices

- Special Effects: Such as magnetoresistance, hall effect devices and magnetic resonance

Magnetizing Fixtures/Tooling

Magnetization is a key step in the manufacture of any permanent magnet component and is usually the last stage in the manufacturing process. While simple 2 pole magnets can be magnetized in one of our standard solenoid magnetizing coils, multi-pole magnets need their own custom-made fixtures. Bunting-DuBois designs and manufactures all our own magnetizing fixtures either for use in house or to be used on customers’ own equipment. Due to the high energies required to generate the magnetizing fields, particularly for rare-earth magnets, production magnetizing fixtures are designed with water cooling and significant safety interlocks to protect the operators and also to ensure the fixtures can never be operated with the wrong settings resulting in only partially magnetized components. Production fixtures are built for the life of a project.

Prototype Magnetizing Fixtures/Tooling

For development projects, prototype fixtures can be built quickly after design. These allow for a small quantity of magnets to be magnetized and built into a prototype build program. Prototypes usually do not have the built in cooling or interlock features and can only be guaranteed for small volumes.

Magnetizing Systems

For customers who wish to bring the magnetization process in house, Bunting-DuBois can supply turnkey magnetizing systems for integration into a production line. This can range from magnetizing fixtures to run on customers’ own magnetizing equipment or full systems which include both the capacitor discharge magnetizing unit and fixtures.

Bunting-DuBois manufactures our own capacitor discharge units which are all PLC controlled and therefore can be integrated into customers’ own production lines. The units employ all the same interlock and safety features for production including magnetization fixture temperature control. Through appropriate consultation with customers, Bunting-DuBois will manage the process to ensure the magnetizing system meets the production requirements in the most efficient way.

Post Assembly Magnetization

From a production point of view, the most desirable approach is to build a multi-pole magnet assembly with un-magnetized magnets and then magnetize the assembled device as the final step in the manufacturing process. This avoids all the production issues associated with handling and locating very strong magnets. This process is called post assembly magnetization. Multi-pole magnetizing fixtures can be built to post-assembly magnetize customers’ own assemblies or those assembled by Bunting-DuBois. It is not always possible to achieve 100% saturation throughout the magnet volume but the effect of this can be simulated by Bunting-DuBois using our specialized FEA software so that customers can assess if the practical and cost advantages of post assembly outweigh the disadvantages of a slight drop in performance.

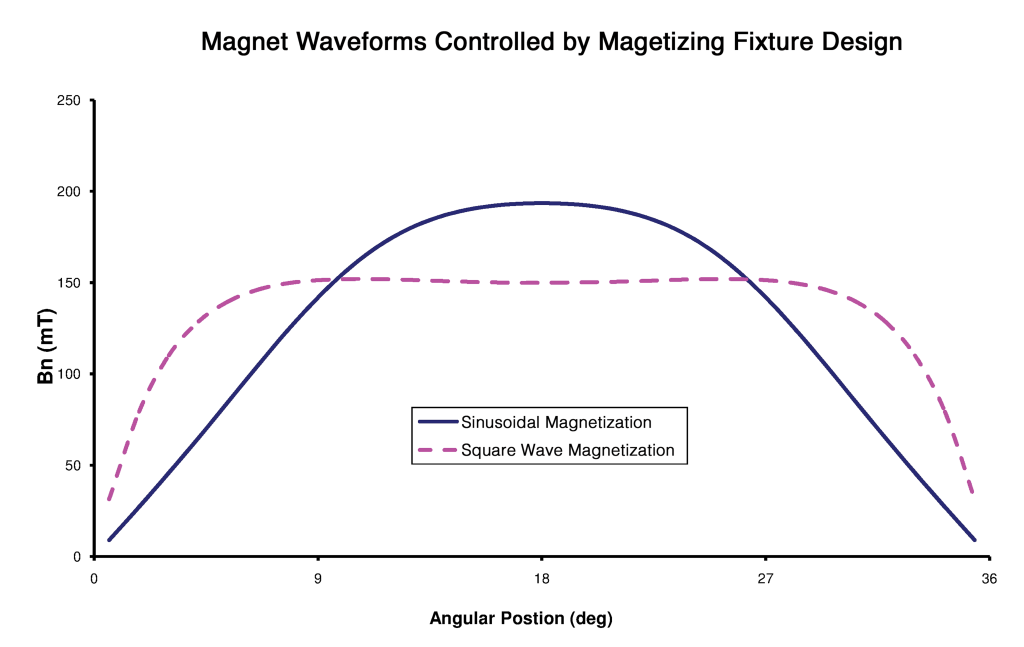

Magnetization Waveforms

In addition it allows us to design magnets with specialized flux density wave forms to meet specific customer requirements, whether it be for encoders, general switching magnets or rotor magnets for permanent magnet motors. On radially magnetized parts or assemblies it is possible to skew the poles to help reduce cogging torque and for isotropic magnet ring magnets, square waves, trapezoidal or sinusoidal waveforms this can be achieved, sometimes to within a few percent total harmonic distortion. Increasingly there is a demand for very complex multi-pole, multi-track systems that require a very careful choice of materials to ensure requirements are met.

Halbach Magnetization

Halbach arrays or cylinders are a particular type of permanent magnet assembly which produces a field on one face of the assembly while canceling out the field on the other side. In the case of a cylinder, the field will be concentrated into the center of the cylinder with zero field on the outside. In other words, it is completely self shielding. A true Halbach can only be achieved with a sinusoidally varying field distribution within the assembly. Close approximations to Halbach arrays can be achieved with arrays of magnet blocks but single isotropic ring magnets which can be multi- pole magnetized with continuously varying fields are ideal for this technology. Through careful design of the magnetizing fixture, close approximations to Halbach arrays can also be achieved without having to use complex multiple segment magnet assemblies which are both difficult to assemble and expensive.