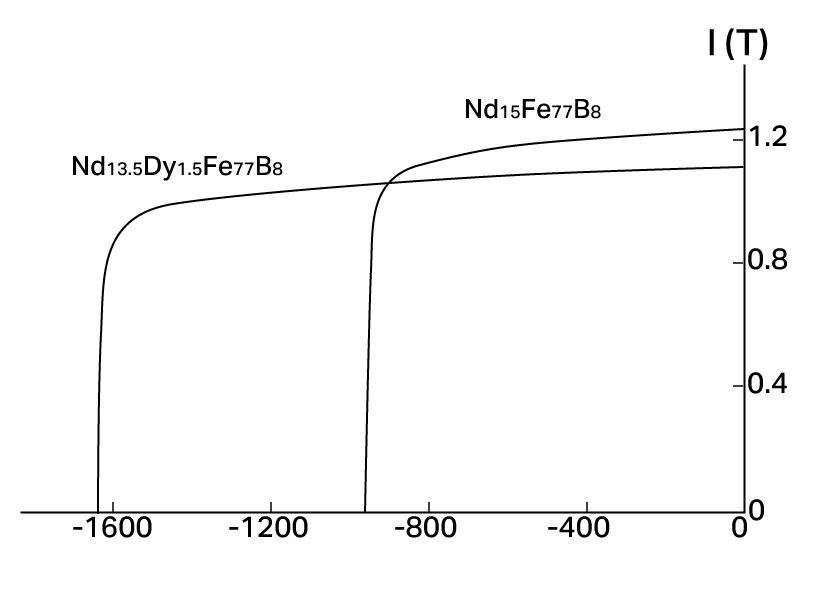

Despite their commercial success, NdFeB magnets suffer from two significant problems. These are: poor corrosion resistance and a high thermal coefficient of coercivity, α(HcJ), which can be as high -0.65%/°C, compared to alnico magnets with an α(HcJ) of -0.01%/°C. The temperature sensitivity of NdFeB limits its maximum operating temperature. The corrosion resistance issue has been virtually eliminated by a combination of improved processing, microstructure refinement, grain boundary modification, alloy chemistry and hermetic coatings. However, it is interesting to note that the solution employed today for increasing the operating temperature of an NdFeB magnet was discovered back in 1984; namely the addition of HREE elements and in particular Dy and Tb (see Figure 1). As can be seen, a small addition of Dy significantly increases the intrinsic coercivity, HcJ, compared to the standard magnet composition.

Figure 1. Effect of Dy Substitution in Coercivity of NdFeB Magnets

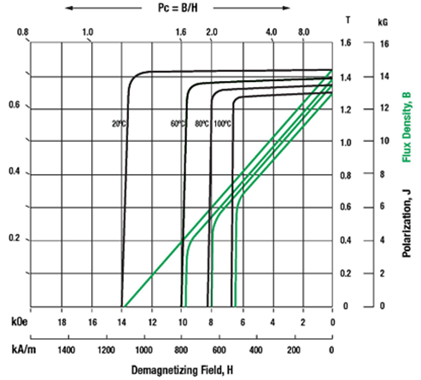

Figure 2 demonstrates an example of the demagnetization behavior of sintered NdFeB grade N55M at different temperatures. Note the effect of increasing temperature on both remanence, Br, and coercivity, HcJ: both Br and HcJ decrease with increasing temperature. This particular grade loses around 50% of the room temperature coercivity at 100°C.

Figure 2. Effect of Temperature on Coercivity of NdFeB Magnets

Of course, this is a major issue in any application operating at elevated temperature, particularly when the magnets are subject to a significant demagnetizing field at the same time, e.g., a servo motor working significantly above room temperature when under high torque operating conditions, which can lead to demagnetization of the magnets and loss of motor performance or even total motor failure.

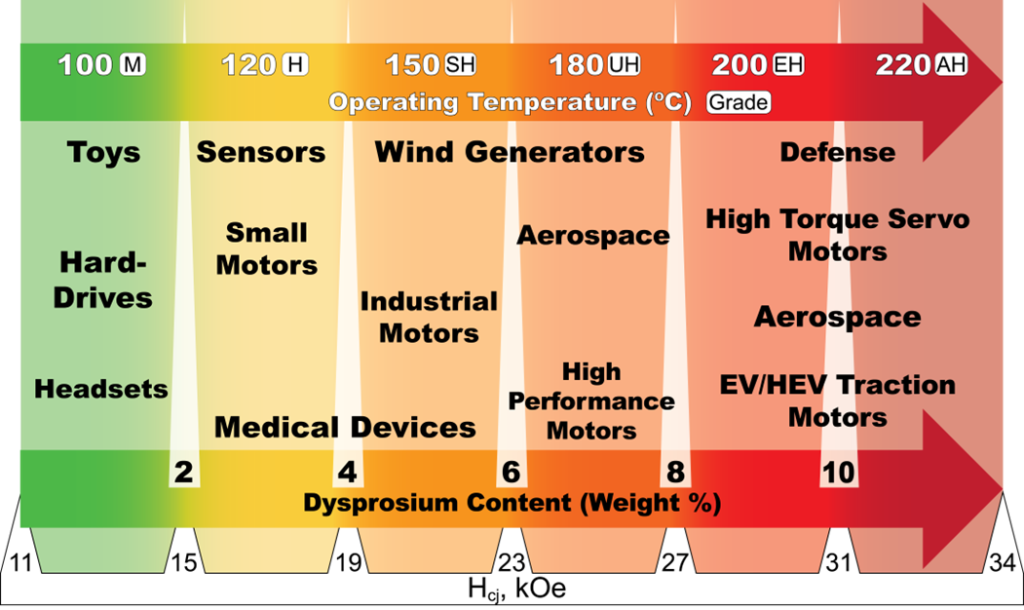

It has become common practice in the NdFeB magnet industry to add Dy (or Tb) to improve coercivity, thermal performance and maximum application temperature. Figure 3 shows the typical NdFeB grade designations that have been developed based on Dy content and the corresponding maximum recommended operating temperature. Typical application areas for each grade are also indicated. As can be seen in Figure 3, increasing Dy content increases the maximum operating temperature from around 80°C to 220°C with an addition of 12 wt.% Dy content.

Figure 3: NdFeB grades and corresponding HREE content

Beginning in 2011, the Chinese authorities placed restrictions on the export of REE and products resulting in supply disruptions, speculative stockpiling, and extraordinary price increases e.g., Dy2O3 prices increased twelve times and Tb4O7 over 6 times. This price spike led to extensive research efforts throughout the industry, particularly in Japan and China, to find ways to reduce the Dy content for higher temperature/coercivity grades.

What happened is that several major magnet producers developed similar approaches to this problem by using processes that essentially enriched the grain boundary regions of the main Nd2Fe14B phase with HREEs by a variety of solid state, gaseous and other forms of diffusion technologies. Since the coercivity in these materials is controlled primarily in the grain boundary region, these Dy-diffusion techniques have the advantages of enhancing coercivity, while at the same time, minimizing the loss of remanence and reducing the amount of Dy required compared to the conventional bulk alloying methods.

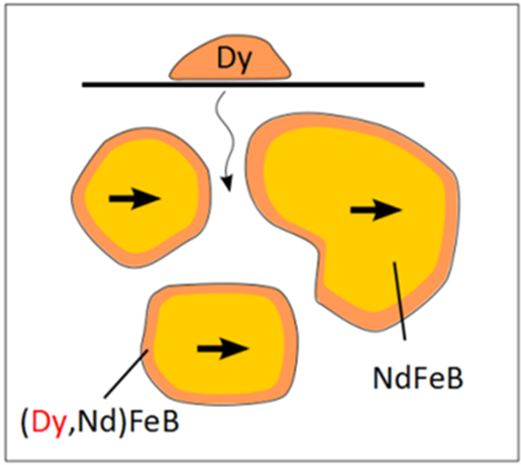

One example of this approach is the TDK HAL (High Anisotropy Field Layer) process. In the HAL process, a Dy diffusion source is applied to the surface of a sintered neodymium magnet substrate, and then heat treated. The Dy diffuses throughout the grain boundary regions of the material via the grain boundary Nd-rich phases that surround the Nd2Fe14B main phase particles. Since the heat treatment used in the HAL process is performed at relatively low temperatures, Dy does not diffuse into the interior of the crystalline particles. This is shown diagrammatically in Figure 4.

Figure 4. Schematic of Grain Boundary Dy-Diffusion Process

TDK claims a 20 to 50% reduction in Dy is possible with their HAL technology with a 3 to 5% increase in Br. Today all the major NdFeB manufacturers offer some variant of a grain boundary diffused or modified reduced Dy content grades. So why do the standard bulk alloy grades still exist? The answer is processing cost versus HREE raw material price and the limitation of magnet dimensions, particularly thickness.

All these grain boundary diffusion processes are rather slow, primarily due to the low temperature annealing required. So, for the economics to be favorable, Dy raw material prices must be above a certain level. Of course, with the expected growth to EV/HEVs over the next 10 years, demand for Dy and Tb will exceed supply at some point for conventional alloyed grades. At this point grain boundary diffused grades may take over for the highest operating temperature applications.