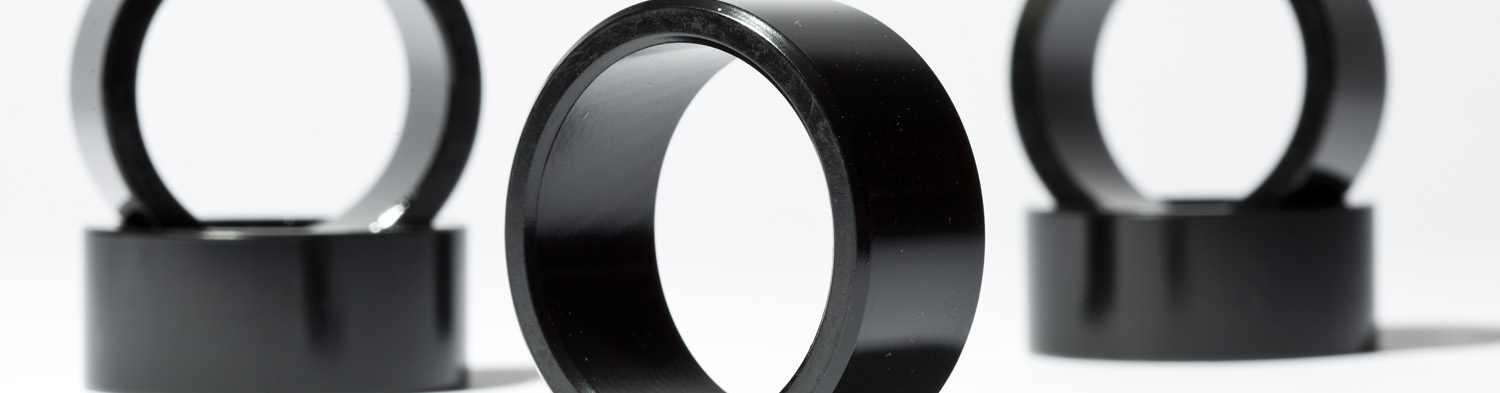

Magnets for Sensing and Switching Assemblies

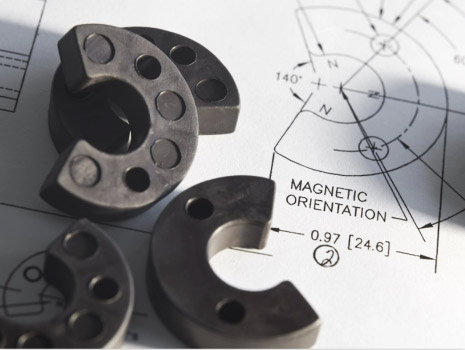

- 2D and 3D magnetic modeling of your design

- Rapid prototyping of designs

- Capacity to manufacture magnets + magnetic assemblies in any quantity

- Extensive quality checks of product

- On-time delivery

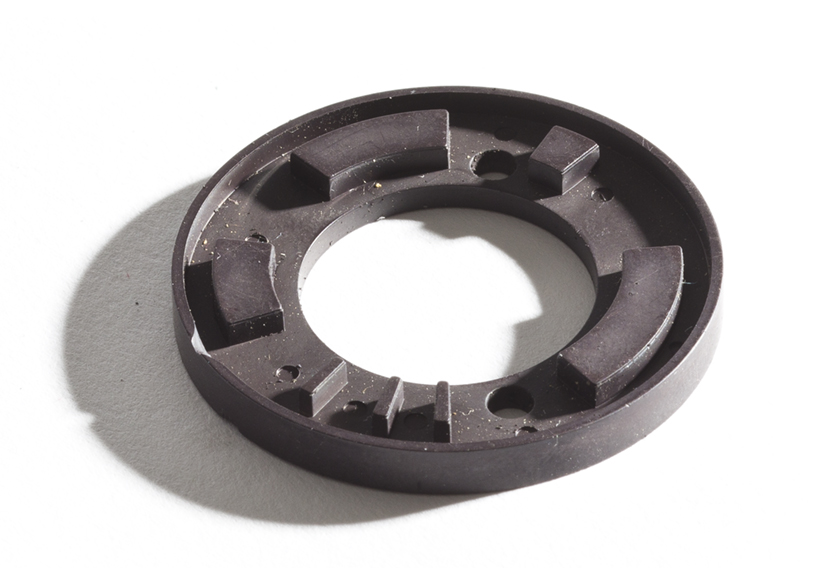

Custom Magnets for Sensing and Switching Assemblies

Sensing and switching assemblies utilize magnets to enable efficient operations. With our magnet-based solutions, you can enhance automation, improve safety, and streamline processes with ease.

At the core of sensing and switching assemblies lies the strategic integration of magnets, enabling accurate detection and control of various parameters. By harnessing the power of magnetism, these assemblies offer a versatile and responsive solution for industries such as automotive, manufacturing, and home automation.

In sensing applications, magnets play a pivotal role in detecting and measuring physical properties such as proximity, position, and speed. By incorporating magnets within the sensing assembly, we create a magnetic field that interacts with target objects. Changes in the magnetic field are then translated into electrical signals, providing real-time feedback on the desired parameter. This allows for precise monitoring and control, facilitating automation and ensuring optimal performance.

Switching operations are also revolutionized by the integration of magnets in these assemblies. Magnets are utilized to trigger or control the opening and closing of circuits, providing reliable and efficient switching capabilities. When a magnet approaches or moves away from a switch assembly, the magnetic field alters, resulting in the activation or deactivation of the switch. This enables seamless control and facilitates automation in applications such as security systems, door sensors, and power management.

One significant advantage of magnet-based sensing and switching assemblies is their durability and reliability. Magnets are highly resistant to environmental factors such as moisture, dust, and vibration, ensuring consistent performance even in demanding conditions. The absence of physical contact in magnet-based sensing and switching also eliminates wear and tear, prolonging the lifespan of the assemblies and reducing maintenance requirements.