Magnetic Couplings

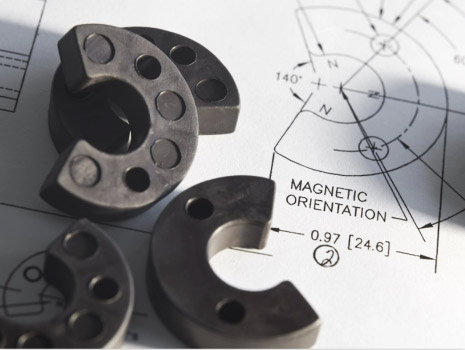

- 2D and 3D magnetic modeling of your design

- Rapid prototyping of designs

- Capacity to manufacture magnets + magnetic assemblies in any quantity

- Extensive quality checks of product

- On-time delivery

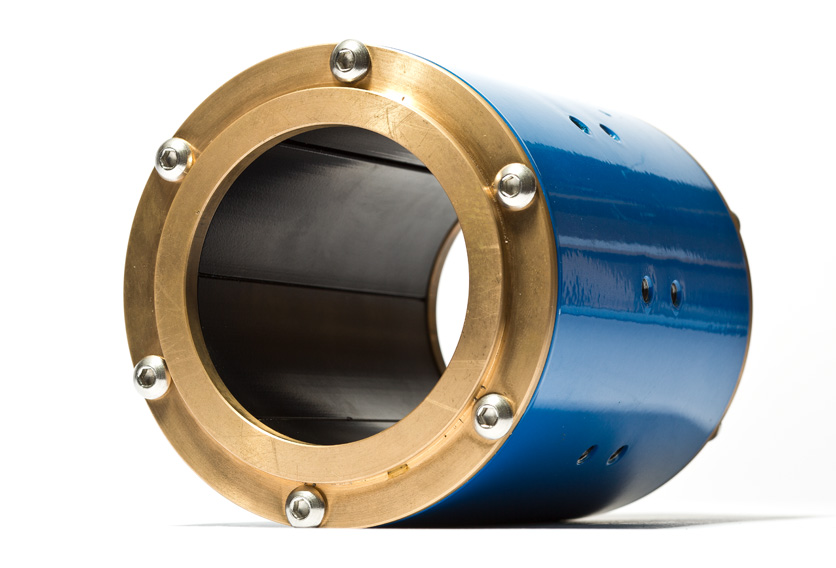

Custom Magnet Assemblies for Magnetic Couplings

Magnet assemblies play a crucial role in magnetic couplings, a sophisticated mechanism used to transmit torque and motion between two rotating components without physical contact. By utilizing the power of magnetism, magnetic couplings offer numerous benefits, including improved efficiency, reduced maintenance, and enhanced safety.

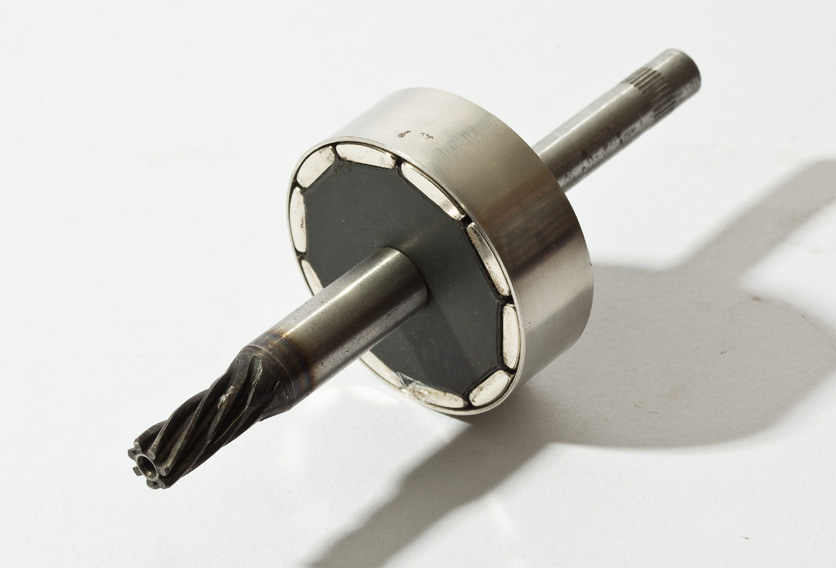

At the heart of a magnetic coupling are two main components: an outer and an inner rotor. The outer rotor is typically connected to a motor or a power source, while the inner rotor is connected to the driven load. These two rotors are magnetically coupled, enabling torque transfer through a non-contact magnetic field.

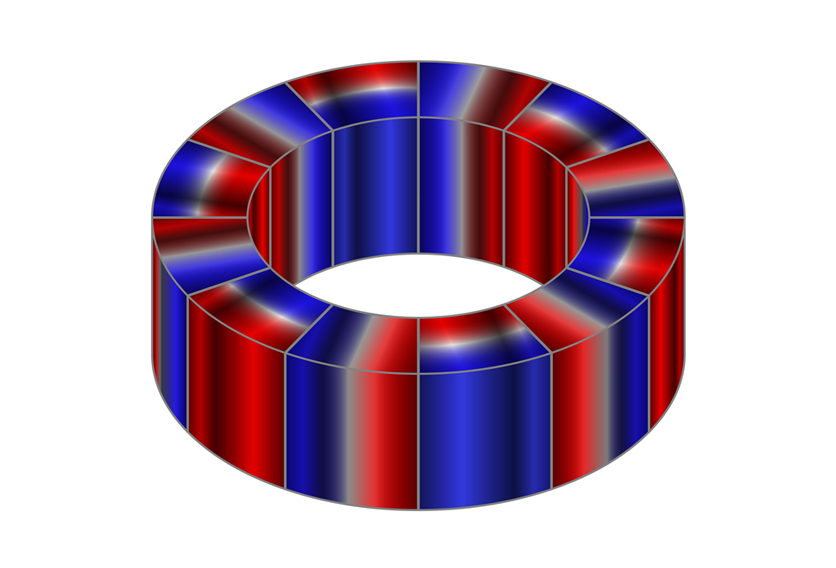

Permanent magnets are strategically placed in both the outer and inner rotors to create a magnetic circuit. The magnets in the outer rotor generate a magnetic field that permeates the space between the two rotors. This magnetic field interacts with the magnets in the inner rotor, establishing a force that transfers torque from the outer to the inner rotor.

The magnets are arranged in a specific configuration, such as in a radial or axial orientation, to optimize the magnetic flux and maximize the torque transfer efficiency. The strength and polarity of the magnets are carefully designed to ensure a secure magnetic coupling while allowing for easy disengagement when required.

One significant advantage of magnetic couplings is their ability to provide a hermetic seal between the driving and driven components. In applications where a fluid or gas needs to be contained, such as pumps or mixers, a magnetic coupling can eliminate the need for traditional mechanical seals that are prone to wear and leakage. The non-contact nature of magnetic couplings ensures a leak-free operation, enhancing reliability and reducing maintenance costs.

Another benefit of magnetic couplings is their ability to provide overload protection. In the event of an excessive load or a sudden increase in torque, the magnetic coupling can disengage, preventing damage to the driving or driven components. This feature helps safeguard the equipment and improves operational safety.

Magnetic couplings also offer the advantage of silent operation and reduced vibration. The absence of physical contact between the rotors eliminates friction and associated noise. Additionally, the magnetic coupling acts as a damping element, minimizing vibrations and contributing to a smoother operation.