One of the most discussed topics in industry for the past few years has been the subject of automation. Automation is a rapidly growing field that presents thousands of possibilities, and has the potential to completely change the world of manufacturing as we have known it for years. At the company’s PA facility, Bunting-DuBois is embracing the power of automation to meet modern industry challenges.

The products Bunting-DuBois manufactures are in exceptionally high demand, and many of our orders require operations to take place 24 hours a day, 7 days a week in order to successfully fill the customer’s needs. In addition to high demand, some of our products demand an extremely intricate assembly process and level of precision in assembly that is not humanly possible to achieve. Even if human labor could reach the necessary level of precision, the amount of people required to hit production targets that customers require would make the product cost prohibitive.

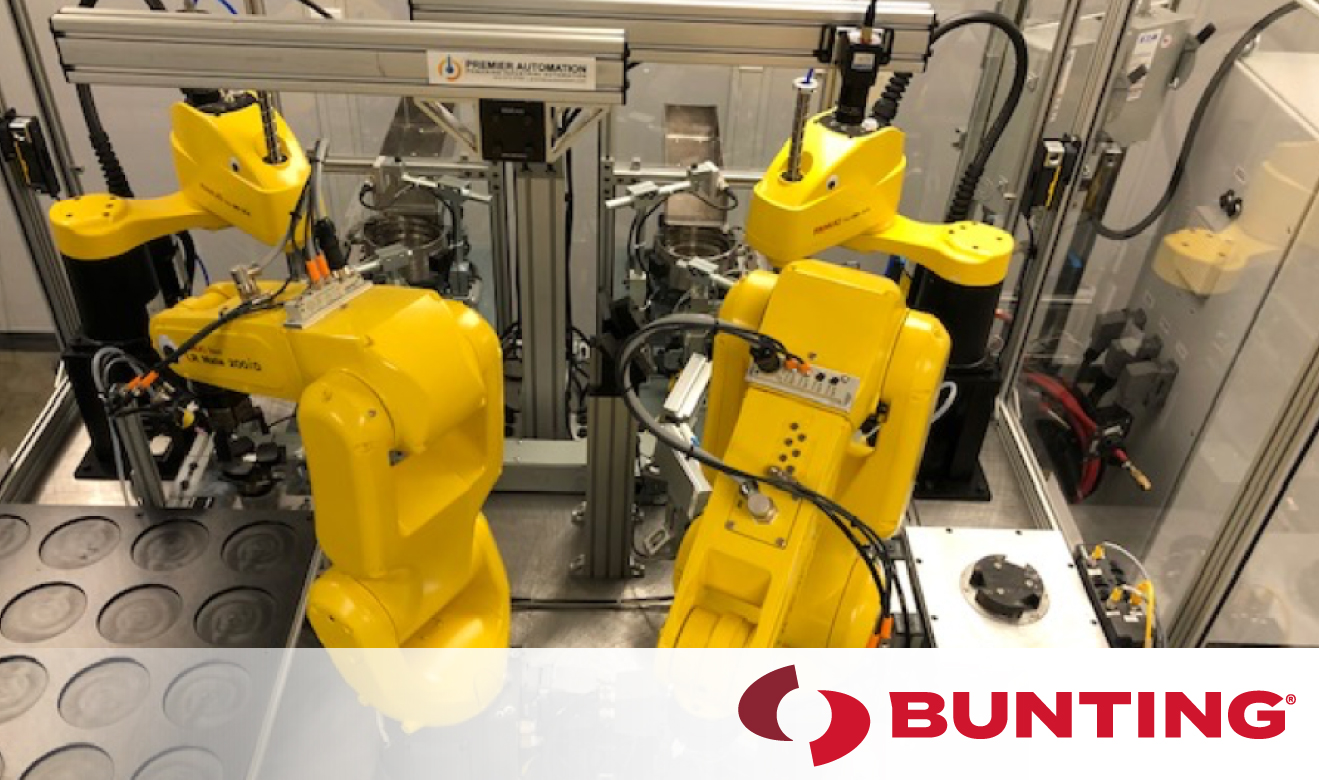

Bunting-DuBois utilizes an automated assembly and magnetization system to produce large quantities of precisely assembled, high quality product despite challenging time constraints.

Bunting’s automated assembly and magnetization system improves product quality while minimizing cost. This high end system has four robots, two camera vision systems, two gluing stations (to assist in part assembly), and one magnetizing and polarity checking station. At the DuBois facility, this system works at an incredible pace to create parts at speeds that would be impossible for human labor to achieve, let alone maintain for extended periods of time.

Bunting-DuBois uses Automation to Improve our capabilities for producing custom designed magnets and permanent magnet assemblies.

Automation at Bunting-DuBois allows for the knowledge and skills of our employees to be utilized to their full potential. As robots labor tirelessly to assemble and magnetize parts, the employees of the facility are free to work on other projects that demand the critical design expertise that no robot could ever replicate. Rather than breaking their backs in meticulous assembly tasks, Bunting employees at DuBois are free to work on the challenging engineering projects that characterize our company—custom design solutions.

At Bunting, we utilize automation to meet high demand with no sacrifice to product quality. Automation helps our team perform to the best of their abilities, and by using automation to take care of the repetitive tasks, we are able to focus on designing new, innovative products for our customers. To learn more about our custom engineering capabilities, our manufacturing process, and the industries we serve at Bunting, Contact Us Today.